1.Application:

JBS-C Touchscreen Digital Display Semi-automatic Charpy Impact Testing Machine is used for measuring the metal material resistance performance under dynamic load, in order to determine the material properties under dynamic load.

It’s a necessary testing machine, not only used in the metallurgy, machine manufacture etc areas, but also used for the science research.

2.Description:

The equipment is simple operate with High Efficiency, Raise Pendulum, Hanging Swing, Feeding, Positioning, Shock and Temperature Adjustment Settings are controlled by a microcontroller, equipped with special feeding device automatic feeding, automatic sample face orientation. Sample baked to impact time is less than two seconds, meet the requirements of low-temperature metal Charpy impact test method.

It can use the remaining energy to automatic Raise Pendulum after impact the sample, prepare for the next test preparation, high efficiency.

3.Features:

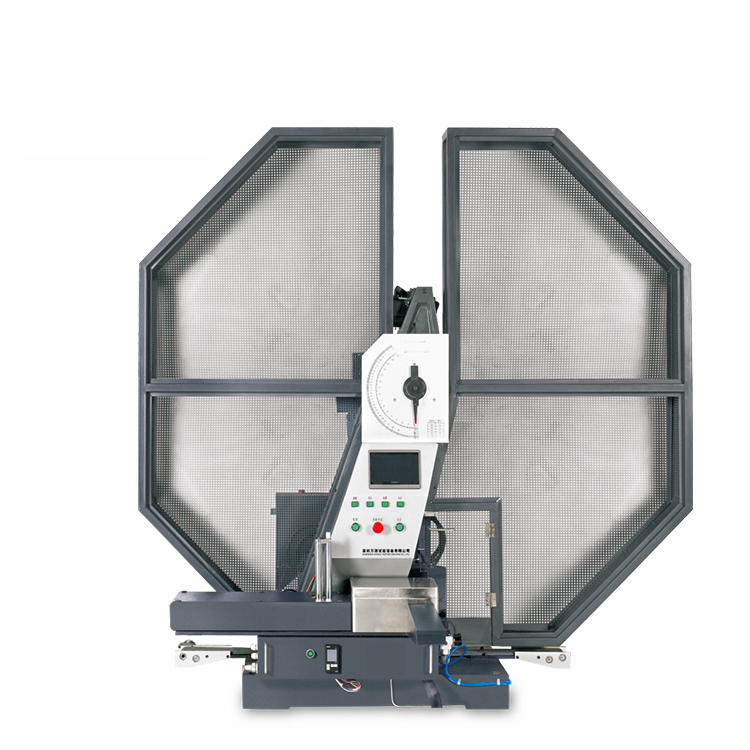

3.1 Main frame is dual prop, shaft simply supported beam supporting, hanging pendulum, a

reasonable distribution of radial load bearing host stiffness, particularly suitable for large

energy impact test.

3.2 Standard dual-stage reducer mention hammer, smooth operation.

3.3 Hanging pendulum device using buffer device, hanging pendulum steady.

3.4 Pendulum 3D design, to ensure the combat center accurate, precise moment the pendulum.

3.5 Shock knife with screw mounting, easy replacement.

3.6 Main frame is equipped with safety pins, and is equipped with a fully enclosed safety net.

4.Technical Specifications:

| Model | JBS-300C | JBS-450C | JBS-600C | JBS-750C |

| Control Method | Single Chip Control | |||

| Max. Impact Energy | 300 J | 450 J | 600 J | 750 J |

| Impact Speed | 5.24 m/s | |||

| Pre-rising Angle Of The Pendulum | 150° | |||

| Angle Accuracy | ±0.1° | |||

| Specimen Bearer Span | 40 mm | |||

| Round Angle Of The Jaw | R 1.0~1.5 mm | |||

| Round Angle Of Impact Edge | R 2.0~2.5 mm (Special Order: R8±0.05 mm) |